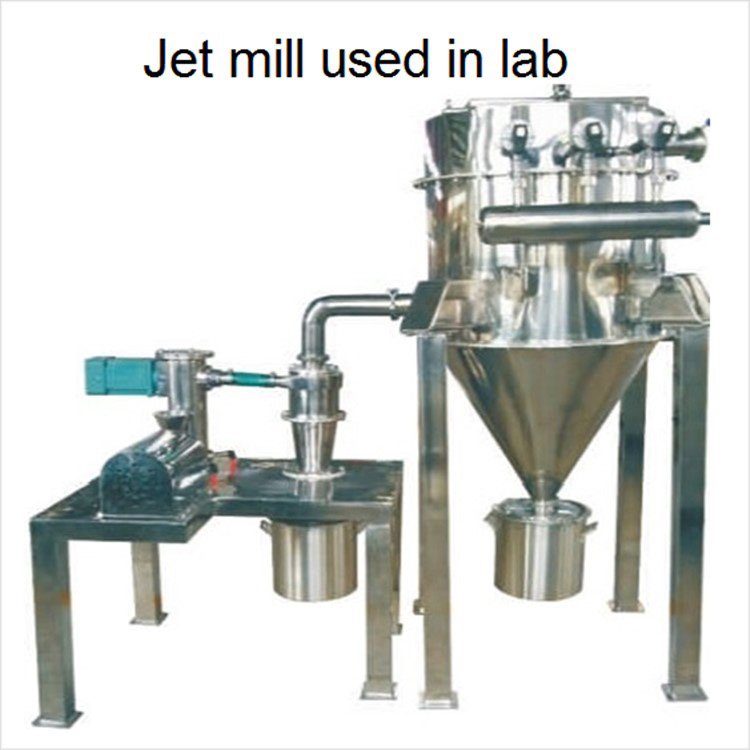

Lab-siv Fluidized-bed Jet Mill Rau 1-10kg Peev Xwm

Jet Mill siv nyob rau hauv Lab, uas nws cov ntsiab lus yog raws li lub hauv paus ntsiab lus ntawm lub fluidized txaj Jet Mill yog xws li ib tug ntaus ntawv raws li kev siv lub high-speed airflow los ua lub qhuav-hom superfine pulverizing.Cov nplej tau nrawm nrawm rau hauv cov cua kub ceev.

Cov ntaub ntawv yuav yog hauv av los ntawm kev ua kom nrawm nrawm thiab sib tsoo ntau zaus nyob rau hauv nruab nrab ntawm cov cua kub ceev.Cov ntaub ntawv pulverized yog sib cais los ntawm lub log grading thiab cov khoom yuav tsum tau sib cais ces sau los ntawm Cyclone Separator thiab Collector, cov ntaub ntawv coarser raug xa rov qab mus rau lub milling chamber rau ntxiv pulverizing kom txog rau thaum lawv mus txog qhov yuav tsum tau loj.

1.Mainly rau Tsawg peev xwm xav tau, 0. 5-10kg / h, haum rau siv hauv Lab.

2.Lub tsev yog tsim los ua ib qho kev sib cog lus sab hauv los ua kev kaw lub voj voog milling.

3.Tsis muaj qhov kub thiab txias, tsis tshua muaj suab nrov, tsis muaj impurity, tsawg pov tseg thaum lub sij hawm milling.

4.Small dimension, compact shape, haum rau siv hauv Lab.Lub kaw lus txais yuav ntse kov npo tswj, ua haujlwm yooj yim thiab tswj kom raug.

5.Nrog huab cua pov thawj zoo, xyuas kom huv si.Kev ua haujlwm yooj yim thiab kev saib xyuas, kev siv cov khoom siv tsis siv neeg.

6. Kev ntsuas dav dav:lub crushing fineness ntawm cov khoom yuav raug tswj los ntawm kev kho cov kev sib hloov ceev ntawm lub grading log thiab lub system.Feem ntau, nws tuaj yeem ncav cuag d = 2 ~ 15μm

7. Tsawg zog noj:Nws tuaj yeem txuag tau 30% ~ 40% lub zog piv nrog lwm cov pa pneumatic pulverizers.

8.Tsawg hnav: Vim tias cov nyhuv crushing yog tshwm sim los ntawm kev cuam tshuam thiab kev sib tsoo ntawm cov khoom, cov khoom siv ceev ceev tsis tshua muaj kev cuam tshuam ntawm phab ntsa.Nws muaj feem xyuam rau crushing cov khoom hauv qab Moh's Scale 9.

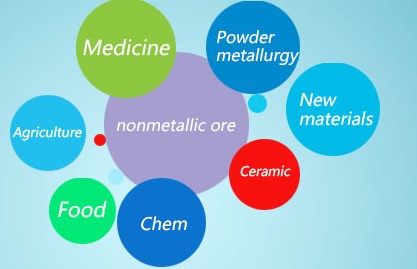

APPLICATON SCOPE

Nws yog dav siv rau superfine pulverizing rau nonmetallic ores, tshuaj metallurgy, western tshuaj, tsoos suav tshuaj, tshuaj ua liaj ua teb thiab ceramics, haum rau siv nyob rau hauv Lab.

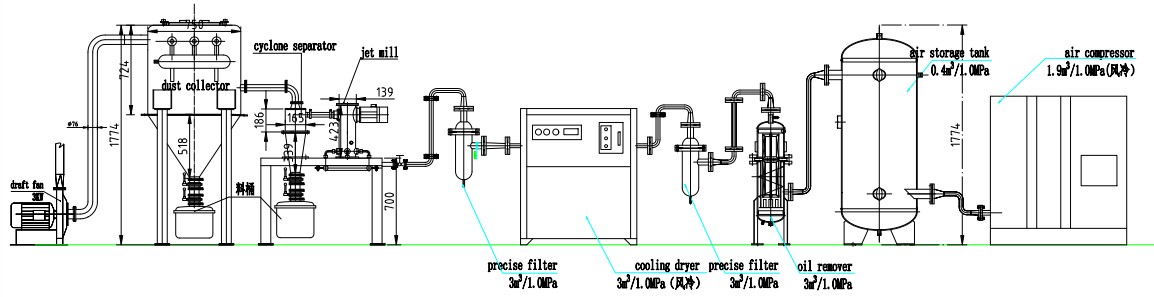

Flow chart ntawm Fluidized-bed Jet Mill

Daim ntawv qhia ntws yog txheej txheem milling ua, thiab tuaj yeem hloov kho rau cov neeg siv khoom.

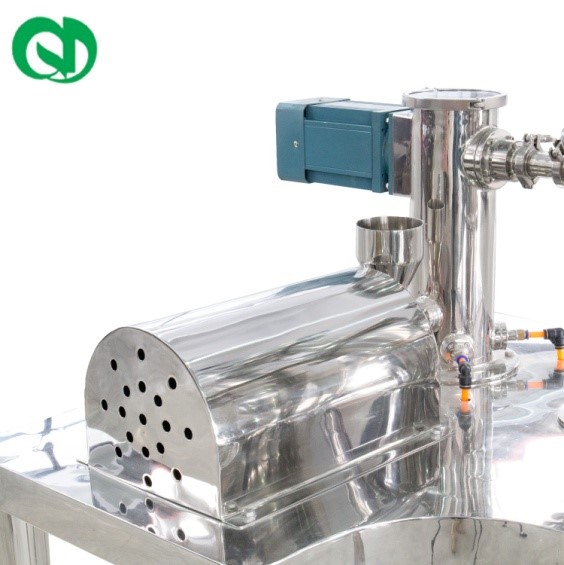

Tshuab Paub meej tsim

1. Cov qauv yog yooj yim, nrog lub qhov ntxuav, yooj yim los ntxuav

2. Lub cev muaj zog nrog lub hau kom tsis txhob noj hmoov

3. Compact qauv: txoj hauj lwm ntawm cov av yog me me

Kev pabcuam ua ntej:

Ua raws li tus kws pab tswv yim zoo thiab tus pab cuam ntawm cov neeg siv khoom kom lawv tau txais kev nplua nuj thiab muaj txiaj ntsig zoo rov qab los ntawm lawv cov peev txheej.

1. Qhia cov khoom rau cov neeg siv khoom kom ntxaws, teb cov lus nug uas tau tsa los ntawm cov neeg siv khoom kom zoo;

2. Ua cov phiaj xwm xaiv raws li qhov xav tau thiab cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom hauv ntau qhov chaw;

3. Kev them nyiaj yug kev sim ua qauv.

4. Saib peb lub Hoobkas.

Quality Assurance

1. nruj me ntsis raws li ISO9001-2000 kev tswj xyuas zoo;

2. Kev tswj nruj nruj los ntawm kev yuav khoom tshuaj xyuas, kev soj ntsuam cov txheej txheem mus rau qhov kawg pov thawj;

3. Tsim kom muaj ntau lub koom haum QC los ua cov kev tswj xyuas zoo;

4. Cov qauv kev tswj xyuas kom zoo:

(1) Ua kom tiav cov ntaub ntawv rau kev tswj xyuas zoo thiab cov lus pom zoo;

(2) Kev tshuaj xyuas nruj rau cov khoom ntawm peb cov khoom sib tsoo, kom paub tseeb tias cov khoom tsis muaj kev puas tsuaj thiab zam

xeb-noj thiab xim tev tawm tom qab.

(3) Tsuas yog cov khoom tsim nyog yuav raug sib sau ua ke thiab tag nrho cov khoom siv yuav tsum tau kuaj xyuas ua ntej muag.

Kev them nyiaj yug Tech

Raws li kev pom zoo muag, peb yuav muab cov kev pabcuam hauv qab no:

1. Tsim rau koj cov kab ntau lawm ntws thiab cov cuab yeej layout, dawb xwb;

2. Muab cov duab kos duab ntawm cov neeg siv khoom sib tsoo mills thiab kos duab ntawm cov khoom sib xws, thiab lwm yam;

3. Technical parameters ntawm peripheral khoom yuav muab;

4. Cov lus qhia pub dawb rau kev kho cov cuab yeej layout thiab daim ntawv thov;

5. Cov khoom siv kho dua tshiab (cov neeg siv khoom yuav tsum tau them tus nqi);

Kev Pabcuam Tomqab Muag

1. Peb yuav xa peb cov kws tshaj lij mus rau qhov chaw rau kev taw qhia cov cuab yeej teeb tsa thiab commissioning.

2. Thaum lub sij hawm installation thiab commissioning, peb muaj kev cob qhia neeg ua hauj lwm kev pab cuam.

3. Hnub lees paub qhov zoo yog ib xyoos tom qab commissioning.Thiab tom qab ntawd, peb yuav sau tus nqi yog tias muab kev kho rau koj cov khoom siv.

4. Kev tu cov khoom siv tsis ua haujlwm los ntawm kev tuav tsis raug (tus nqi tsim nyog yuav raug sau).

5. Peb muab cov khoom siv nrog tus nqi zoo thiab kev saib xyuas zoo.

6. Yog tias xav tau kev kho cov khoom siv tom qab hnub tas sij hawm, peb yuav sau nqi kho.