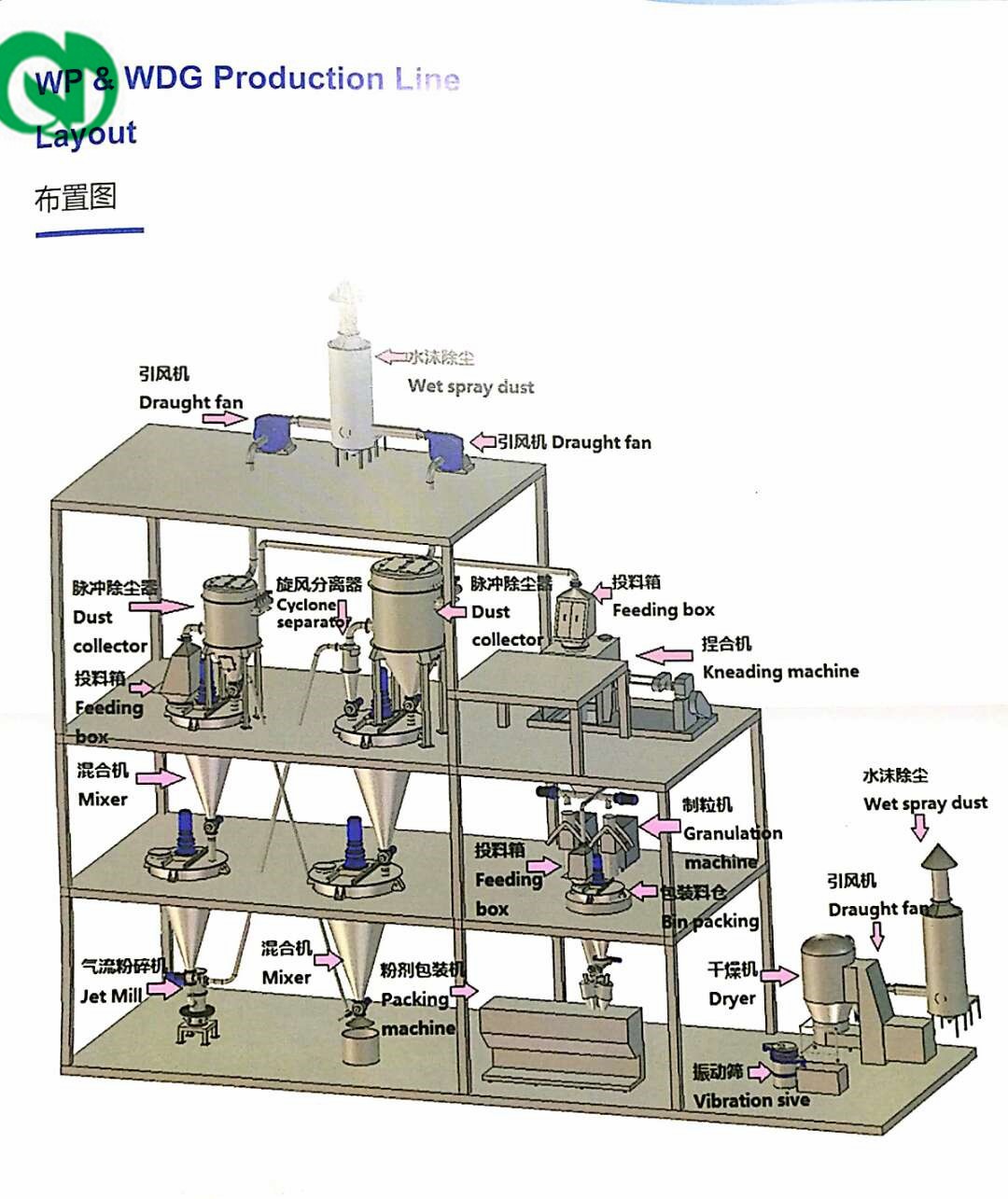

WP-WDG System-Thov rau Agrochemical Field

WP part

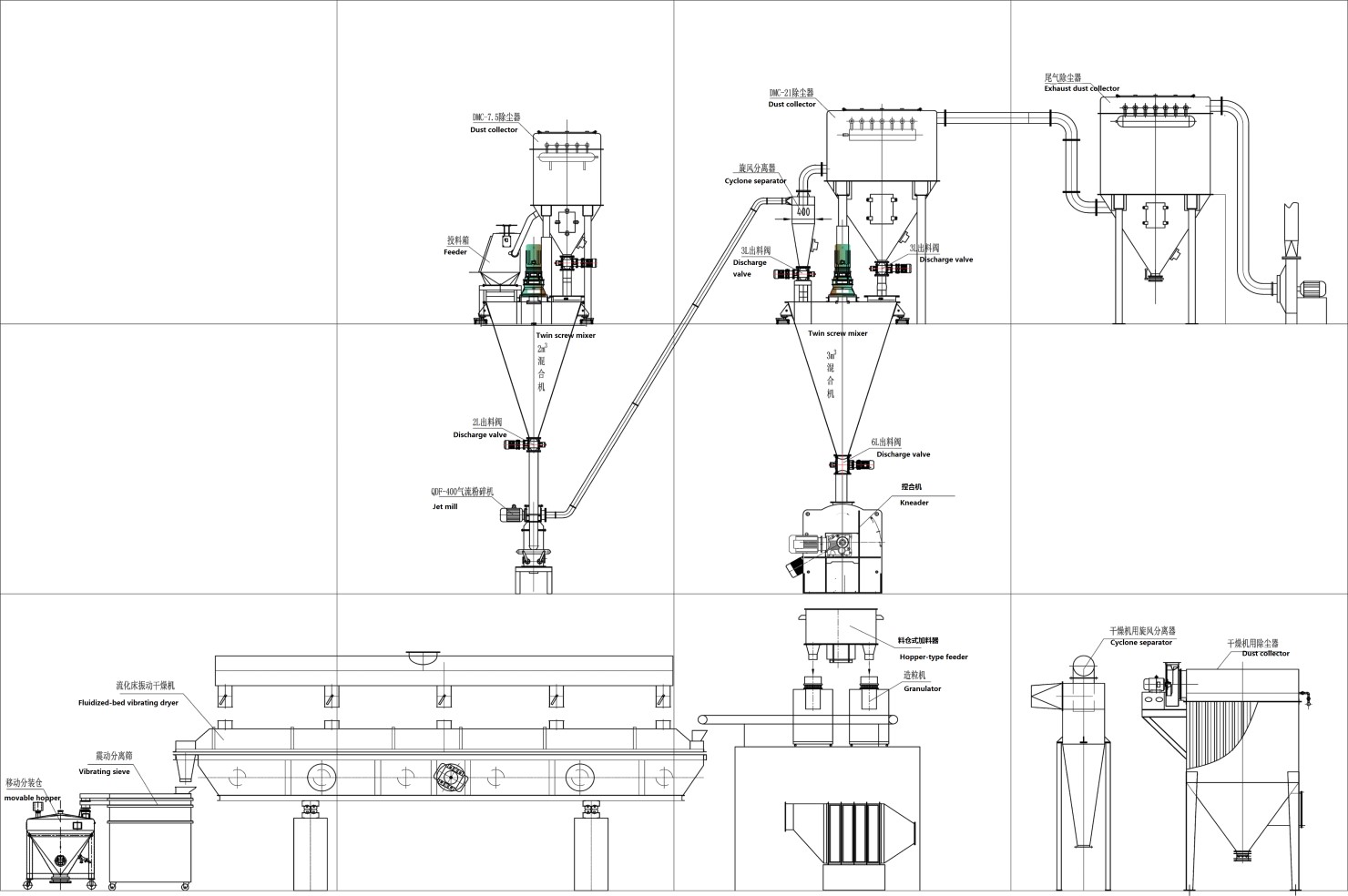

Ua ntej, raw khoom noj los ntawm feeder - cov khoom hloov mus rau thawj 3 m3tov khoom rau premixing, thiab plua plav collector yuav sau cov plua plav thaum lub sij hawm pub mis, tom qab ntawd cov khoom sib xyaw nkag mus rau hauv QDF-600 dav hlau zeb rau milling, cov khoom tso tawm qhov loj tuaj yeem hloov kho los ntawm kev kho qhov sib txawv ntawm kev sib hloov ceev ntawm lub log classifier,. Tom qab milling, cov khoom yuav hloov mus rau lub cua daj cua dub thiab cov plua plav collector nyob rau sab saum toj ntawm thawj 4m3tov khoom los ntawm centripetal quab yuam ntawm cov cua ntsawj ntshab, ces hloov mus rau qhov thib ob 4m3tov khoom rau kev sib tov ua ntej pob lossis hloov mus rau WDG system.

WP system yog ib qho kev sib xyaw ua ke zoo tshaj plaws ntawm cov tshuab dav hlau tshuab, kev sib xyaw tshuab thiab cov cuab yeej ntse tswj. uas yog cov khoom txaus siab rau cov tshuaj tua kab rau ntau qhov sib xyaw thiab remix, Meanwhile, nws ua tau raws li kev thov ib puag ncig uas tsis muaj plua plav thaum lub sijhawm tag nrho.

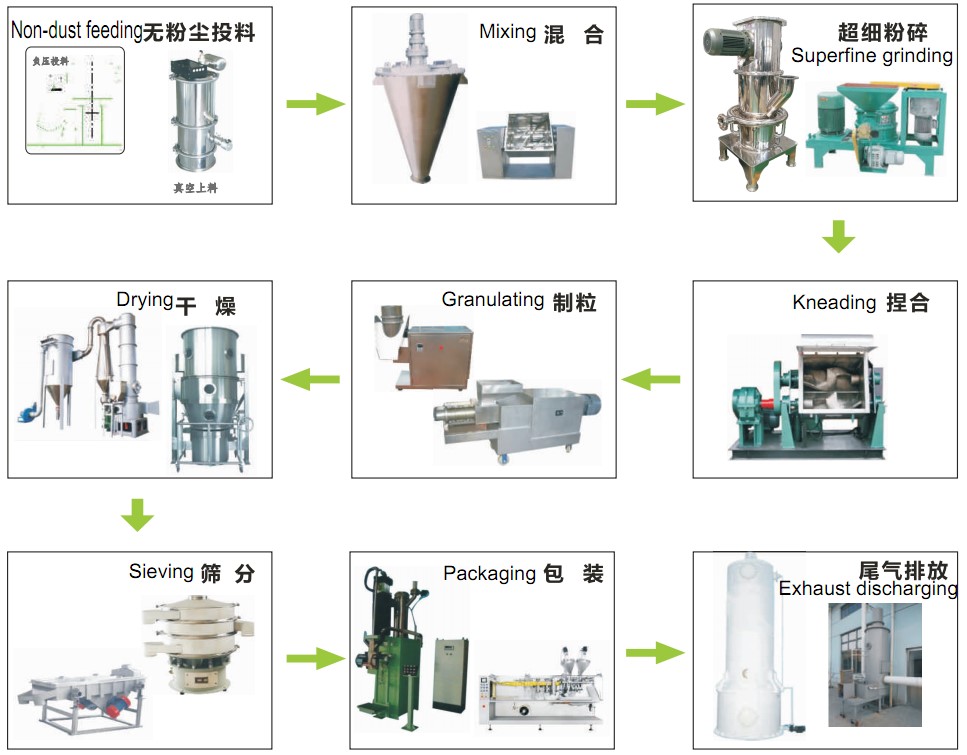

WDG (dej dispersible granule) tseem hu ua wettable hmoov qhuav suspending tus neeg saib xyuas lossis hom nplej, cov khoom siv raw rau cov hmoov ntub dej (WP) tsim los ntawm granulation ib zaug hauv dej, tuaj yeem tawg sai sai thiab tawg, kev npaj granular siab suspended solid dispersion system.

Granulation yog lub hauv paus ntawm tag nrho cov txheej txheem. Granulator yog tus yuam sij kom paub tseeb tias granulated tshuaj tua kab thiab ziab txheej txheem con-figured, uas yog raws li cov yam ntxwv ntawm cov tshuaj tua kab, sim cov ntaub ntawv thiab engineering daim ntawv thov piv txwv, xaiv rotating extrusion granulator los yog twin ntsia hlau extruder granulator. granulator (Fluidized txaj granulation txheej txheem thiab extrusion granulation txheej txheem yog txawv).Qhov yuav tsum tau ntawm noo noo cov ntsiab lus ntawm granulation yog hais txog 8-18%. Raws li cov khoom yam ntxwv thiab ntau lawm txheej txheem, los txiav txim tus tsim ntawm cov txheej txheem mas muaj xws li: kneading, granulation, ziab, tshuaj ntsuam, ntim, cua kub systems, plua plav tshem tawm system.

Ua ntej, cov khoom siv raw yuav raug thauj mus rau hauv 1000L Buffer, ces nws mus rau ZGH-1000 ntsug tov khoom tshuab los ntawm Nqus ZKS-6 rau ntub sib tov ces thauj mus rau hauv XL-450 extrude granulator (3pcs) los ntawm 500L distributor rau ntub granule, ces mus rau QZ5Q-10.9.0. Vibrate Fluid-bed Dryer strip granules ces ZS-1800 centrifugal vibration sieve rau sieve kom tau raws li qhov xav tau granules.

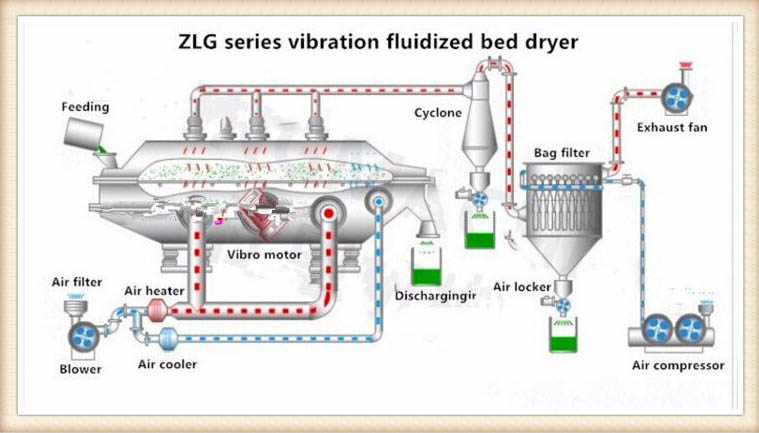

Vibrating kua txaj tshuab ziab khaub ncaws rau tshuaj hmoov

Vibrating kua txaj tshuab ziab khaub ncaws rau tshuaj hmoov

Txoj Cai Ua Haujlwm

Vibration kua txaj yog ib lub tshuab tshiab tsim los ntawm lub hauv paus ntawm lub txaj dej zoo li qub. Mechanical vibration yog ntxiv rau ntawm lub txaj dej. Cov khoom ntub dej nkag mus rau hauv huab cua thiab tsim ib lub txaj dej. Cov khoom raug tshem tawm vim muaj zog txaus siab. Kev vibration ntawm cov pa xa hluav taws xob incite lub fluidization ntawm cov khoom hais thiab txav ntawm cov khoom nyob rau hauv lub txaj dej. Cov khoom siv ua kua tiv tauj cov cua kub thiab tib lub sijhawm ua rau cov cua sov thiab huab cua hloov mus. Cov khoom qhuav yog tso tawm los ntawm qhov chaw nres nkoj tawm.

Yam ntxwv

1. Siv cov tshuab vibrofluidization siab heev, kev puas tsuaj ntawm cov khoom qhuav particle nto yog me me.

2. Kev txav tsis tu ncua, kev hloov pauv tau zoo.

3. Kev vibrations ua rau cov kua dej ntws tawm, qhov ziab ntawm huab cua ntws yog txo, thiab ob peb cov khoom yog entrained.

4. Lub sij hawm nyob rau hauv cov khoom yog zoo ib yam, cov khoom zoo yog uniform.

5. Nws yog siv rau kev ziab ntawm cov khoom siv hluav taws xob hauv lub sijhawm luv luv, xws li, cov dej saum npoo av

ziab ntawm CUSO4·5H2O muaj cov dej siv lead ua, MgSO4·7H2O.

Muaj feem xyuam

Yuav siv tau rau hauv cov txheej txheem qhuav lossis txias, siv tau rau cov khoom loj lossis cov khoom siv thiab tsis yooj yim khiav ntawm cov khoom tsis zoo, lossis vim tias ua kom cov khoom tsis txaus thiab ua kom tiav cov dej ntws tawm ntawm cov khoom thiab yooj yim rau kev sib cog lus, rhiab rau qhov kub kom qhuav thiab muaj cov khoom gesso cov khoom siv dej tshem tawm los ntawm.

Technical parameter

| Qauv | Fluidized txaj cheeb tsam (M2) | Inlet cua kub (oC) | Qhov hluav taws xob cua kub (oC) | evaporation dej muaj peev xwm (kg) | Tsav | |

| Qauv | Kw | |||||

| ZLG3 × 0.30 | 0.9 | 70-140 : kuv | 40-70 : kuv | 20-35 | ZDS31-6 | 0.8 × 2 |

| ZLG4.5 × 0.30 | 1.35 Nws | 70-140 : kuv | 40-70 : kuv | 35-50 | ZDS31-6 | 0.8 × 2 |

| ZLG4.5 × 0.45 | 2.025 Nws | 70-140 : kuv | 40-70 : kuv | 50-70 | ZDS32-6 | 1.1 × 2 |

| ZLG4.5 × 0.60 | 2.7 | 70-140 : kuv | 40-70 : kuv | 70-90 : kuv | ZDS32-6 | 1.1 × 2 |

| ZLG6 × 0.45 | 2.7 | 70-140 : kuv | 40-70 : kuv | 80-100 | ZDS41-6 | 1.5 × 2 |

| ZLG6 × 0.60 | 3.6 | 70-140 : kuv | 40-70 : kuv | 100-130 Nws | ZDS41-6 | 1.5 × 2 |

| ZLG6 × 0.75 | 4.5 | 70-140 : kuv | 40-70 : kuv | 120-140 : kuv | ZDS42-6 | 2.2 × 2 |

| ZLG6 × 0.9 | 5.4 | 70-140 : kuv | 40-70 : kuv | 140-170 : kuv | ZDS42-6 | 2.2 × 2 |

| ZLG 7.5 × 0.60 | 4.5 | 70-140 : kuv | 40-70 : kuv | 130-150 Nws | ZDS42-6 | 2.2 × 2 |

| ZLG 7.5 × 0.75 | 5.625 ib | 70-140 : kuv | 40-70 : kuv | 150-180 Nws | ZDS51-6 | 3.0 × 2 |

| ZLG 7.5 × 0.9 | 6.75 ib | 70-140 : kuv | 40-70 : kuv | 160-210 : kuv | ZDS51-6 | 3.0 × 2 |

| ZLG 7.5 × 1.2 | 9 | 70-140 : kuv | 40-70 : kuv | 200-260 Nws | ZDS51-6 | 3.0 × 2 |

General ntawm kev siv

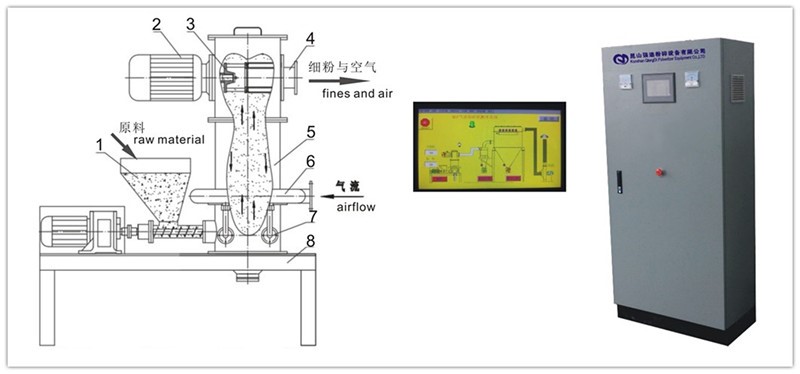

Lub tshuab no siv ib khub ntawm kev sib tsoo cov hniav kom zom cov ntaub ntawv damp rau hauv kem-puab granule los ntawm stainless hlau sieve lub tog raj kheej uas yog muab rau pelletize nyob rau hauv cov txheej txheem tom ntej.Lub tshuab tuaj yeem tau txais qhov sib txawv me me granule los ntawm kev hloov cov stainless hlau sieve.

Nws tuaj yeem ua cov ntaub ntawv ntub dej thiab tau txais qhov sib txawv raws li cov khoom siv thiab kev xav tau.

KEV PAB CUAM:

Lub cev muaj zog lub cev muaj zog yog kis los ntawm daim duab peb sab siv-log rau lub iav lub thawv hauv tus tswv, thiab faib lub zog los ntawm cov khoom sib kis hauv lub thawv iav. Ntxiv cov khoom nyoos rau hauv kev pub noj hopper, nias nws los ntawm saum toj no.

Tom qab sib tov, cov khoom yog ntim rau hauv qhov chaw pub mis thiab raug yuam tawm sab nraud extrusion los ntawm cov hniav tshwj xeeb. Thaum cov khoom ntim rau hauv qhov sib txawv ntawm cov hniav thiab cov ntxaij vab tshaus, cov riam txiav yuav txiav nws mus rau hauv kev sib koom ua ke.

Technical Parameters:

| Ouput | 150-250kg / teev (flake puab), 50-100kg / teev (granule puab) |

| Granule loj | 0.5-2 hli |

| Max siab | 294 Kn (30T) siab |

| Sab sealing siab | 9.8kn ua |

| Pub lub cev muaj zog | 2.2 kwb |

| Granulating Tsav | 2.2 kwb |

| Compressing lub cev muaj zog | 7,5 kwv |

| Pub ceev ceev | 6-33 adjustable |

| Compressing Wheel ceev | 4-25 adjustable |

| Dimension ntawm compressing log | 240 x 100 mm |

| Qhov hnyav (kwv yees) | 2000 Kg |

| Main unit dimension | 1600 X 1000 X 2300 mm |

| Tswj txee dimension | 600 X 400 X 1300 mm |

Kev siv

Lub tshuab yog tsim nyog rau kev lag luam tshuaj, khoom noj khoom haus kev lag luam, kev lag luam dej haus thiab lwm yam, Nws tuaj yeem ua rau cov khoom siv raw khoom sib xyaw ua ke cov qanule xav tau. Tshwj xeeb, nws yog qhov tsim nyog rau cov khoom siv raw uas muaj cov nplaum nplaum.

Nta:

Txhua qhov chaw sib cuag nrog cov khoom siv raw hauv lub tshuab no yog ua los ntawm stainless hlau. Nws qhov tsos yog kev zoo nkauj. Nws tso tawm yog tsis siv neeg.Yog li ntawd nws tuaj yeem zam qhov kev puas tsuaj los ntawm phau ntawv. Nws yog haum rau hauv kab ntau lawm thiab.

Main technical patameters

| Qhov loj ntawm milling riam (mm) | 300 | 400 |

| Txoj kab uas hla ntawm granule (mm) | Φ2 ~ 2.2 (Nws yuav ua tau raws li cov neeg siv khoom xav tau) | Φ1.2 ~ 3 (Nws yuav ua tau raws li cov neeg siv khoom xav tau) |

| Zuag qhia tag nrho Dimensions (mm) | 700 × 540 × 1300 hli | 880 × 640 × 1300 hli |

| Lub cev muaj zog (kw) | 3 | 4 |

| Qhov hnyav (kg) | 350 | 400 |

| Muaj peev xwm (kg / h) | 100-200 | 140-400 Nws |

Txoj Cai

LGH ntsug hom tov khoom yog tsim los ntawm hauv qab xa cov khoom oars thiab kev kub ceev crushing oars, hauv qab oars nruam xa cov khoom mus rau sab saum toj raws phab ntsa ntawm lub thawv.

Kev kub ceev crushing oars rhuav tshem cov khoom tiav ua rau cov khoom siv xws li vortex, kom tiav qhov sib xyaw ua ke hauv lub sijhawm luv luv.

Cov yam ntxwv ntawm cov khoom siv

LGH ntsug hom kev kub ceev sib tov tshuab yog hom tshiab tshaj plaws high-efficiency tov khoom ntawm peb lub Hoobkas, uas tau sau cov txheej txheem siab heev ntawm domestic thiab txawv teb chaws.Lub ntsiab nta yog raws li nram no:

1.Cov khoom hauv qab oars tsis tu ncua xa cov khoom mus rau sab saum toj los ntawm lub zog centrifugal. Thiab cov khoom siv sab saum toj poob mus rau hauv qab ntawm qhov chaw, ua rau cov khoom siv voj voog zoo li vortex.

2.High-ceev crushing oars zom cov khoom loj tag nrho uas xa los ntawm cov hauv qab oars.

3.Cov khoom siv tuaj yeem sib xyaw ua ke hauv ib lub sijhawm luv luv vim yog ob lub oars kev kub ceev kiv puag ncig. Qhov sib tov ceev thiab uniformity yog qhov zoo tshaj plaws nyob rau hauv txhua yam kev sib xyaw tshuab hauv kev lag luam hauv tsev. Lub uniformity yog 100% mix.

4.Start lub discharging valve, tshem tawm ceev ceev heev, thiab lub tshuab yog yooj yim los ntxuav.

5.Lub tshuab kev sib cuag tau ua los ntawm cov hlau tsis muaj steel, thaum lub sij hawm sib tov, cov khoom yuav tsis volatilize, metamorphic thiab ploj.

6.Lub tshuab haum rau sib txawv proportional qhuav thiab ntub cov khoom sib tov, tshwj xeeb tshaj yog haum rau kev sib xyaw ntawm nqaij qaib essence, yaj tshuaj, yaj dej haus thiab lwm yam.

kuj hu ua teb vibro sifter, vibratory sieve.Nws tuaj yeem lim cov kua xws li cov dej khib nyiab thiab cov roj pov tseg thiab lwm yam, tshem tawm cov impurity hauv cov khoom, xws li mis hmoov, mov, pob kws thiab lwm yam.Classify / qib cov hmoov sib xyaw rau hauv ntau qhov sib txawv uas koj xav tau.

Cov lus piav qhia

Teb charcoal / thee ultrasonic vibrating npo sifter tshuab tau txais cov txheej txheem siab heev cov khoom siv tshuaj ntsuam xyuas. Nws muaj cov tsim tawm ultrasonic thiab vibrating npo. Nws yog ib qho tseem ceeb ntawm kev soj ntsuam kev ua tau zoo. Lub tshuab sieving no tau txais kev txawj ntse vibrating ultrasonic maub los thiab tau daws ntau yam teeb meem tshwm sim los ntawm ib zaus, tiag tiag paub qhov tsim nyog ua ke ntawm ultrasonic muaj nuj nqi thiab kev co sieve.

Multi-functions raws li nram no:

1. Kev faib tawm

Hom ntau txheej tuaj yeem tshuaj ntsuam thiab cais tsib pawg ntawm cov khoom sib txawv tib lub sijhawm. Nws yog tsim rau cov ntaub ntawv qhuav.

2. Lim

Kev sib xyaw ntawm cov khoom thiab cov kua tuaj yeem sib cais tau zoo los ntawm ib leeg lossis ntau txheej rau hauv cov ntaub ntawv sib txawv.

3. Tshem tawm cov impurities

Chav tsev tuaj yeem cais ob peb qhov loj lossis qhov me me ntawm cov khoom kom muaj nuj nqis

Kev tu qhov system peb siv ultrasonice ntaus ntawv rau Rotary charcoal / thee ultrasonic vibrating screen sifter tshuab

Cov khoom seem

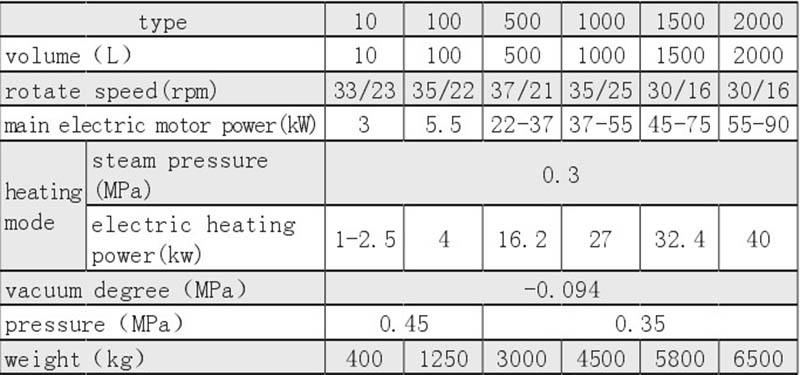

Kneader yog cov cuab yeej zoo tshaj plaws rau kev sib tov, sib xyaw rau cov khoom siv polymerize nrog cov viscosity siab thiab elasto yas. Txhua txheej ntawm kneader muaj ob daim ntawm sigma hniav nyob rau hauv lub w hom mixing chamber. Nws yog dav siv los knead, sib tov, crush, disperse thiab re-polymerize siab viscosity muab tshuaj txhuam los yog elastoplastic cov ntaub ntawv, uas tsis tuaj yeem ua tiav los ntawm cov hmoov mixers thiab kua blenders. Nws tuaj yeem siv rau hauv kev lag luam uas yuav tsum tau muaj rau kev ua haujlwm siab ceev xws li agrichemical, tshuaj, roj hmab, khoom noj khoom haus thiab tshuaj npaj. Cov nyhuv yog zoo dua li tov khoom. Kneader yog cov khoom sib xyaw tshwj xeeb nrog ob lub ntsej muag. Fast ib feem ntau tig ntawm qhov ceev ntawm 42 revolutions ib feeb, qeeb ib qho ntawm qhov ceev ntawm 28 revolutions ib feeb. Kev sib txawv ceev ua kom cov khoom sib tov tau homogenate sai.

Plant Engineering

-Nroog tsim

- Cov txheej txheem saib xyuas, tswj thiab automation

- Kev txhim kho software thiab kev siv lub sijhawm tiag tiag

- Engineering

- Machinery manufacturing

Project Management

- Kev npaj ua haujlwm

- Kev saib xyuas thiab kev tswj xyuas qhov chaw tsim kho

- Kev teeb tsa thiab kev sim ntsuas ntsuas thiab tswj cov tshuab

- Machinery thiab cog commissioning

- Kev cob qhia neeg ua haujlwm

- Txhawb thoob plaws hauv kev tsim khoom

Qhov project txhais

- Kev ua tau zoo thiab kev tshawb fawb lub tswv yim

- Kev suav nqi thiab nyiaj tau los

- Sijhawm sijhawm thiab kev npaj peev txheej

- Kev daws teeb meem Turnkey, cog kev hloov kho tshiab thiab kev daws teeb meem tshiab

Qhov project tsim

- Paub cov engineers

- Siv cov thev naus laus zis tshiab

- Siv cov kev paub tau txais los ntawm ntau pua daim ntawv thov thoob plaws txhua qhov kev lag luam

- Ua kom muaj kev txawj ntse los ntawm peb cov kws tshaj lij engineers thiab cov neeg koom tes